A Key NASA Partner, Global Manufacturer Reaches New Horizons in Textile Performance

When NASA began developing the next generation of space exploration vehicles in 1972 — the first reusable spacecraft in history — they were faced with a particularly daunting and potentially life-threatening challenge.

“The flame within a solid motor burned at 5,700° Fahrenheit, which was hot enough to boil iron,” writes Thomas A. Heppenheimer, noted aerospace researcher and author, in his book Development of the Space Shuttle, 1972-1981. “What was to prevent it from destroying the booster?”

More than half the temperature of the sun itself, the critical motors powering NASA’s space shuttle into orbit presented an incredibly high temperature durability requirement. The solid rocket booster nozzles would need to be reinforced with a unique thermal ablative system to prevent irreparable damage during the mission.

NASA reached out to Tex Tech Industries, a global leader in high-performance material manufacturing, for help in developing a solution.

“Tex Tech has a proud history of being an integral part of the NASA Space program since the development of the space shuttle,” says Justin Barnett, vice president of sales at Tex Tech Industries.

From the first NASA space shuttle reusable solid rocket motor to today’s next-generation Space Launch System, Tex Tech’s materials have made modern space exploration possible. The manufacturer remains the sole provider of U.S.-made carbonizable fabric used not only in the development of solid fueled rocket nozzles for NASA but also for military applications and commercial uses.

Serving diverse customers across the aerospace, automotive, and other key sectors, Tex Tech has continued to reach new horizons in textile performance, including innovative fiber and fabric formation, cutting, and lamination, over its last 115 years in business.

Thomas Insights (TI): You offer a range of standard products, but you also offer custom solutions that are specifically designed to meet unique project requirements. How do you partner with your customers to ensure your products meet their specs?

Justin Barnett (JB): We have a diverse range of capabilities which I equate to having a lot of tools in our toolbox that allow us to work with our customers to create the best science driven solutions instead of one that's constrained by a narrow range of capabilities.

We start by listening to our customers; while this seems to be such a simple concept, I have found that it’s an often-overlooked opportunity. Discussions with the customer help identify not only the necessary attributes for the fabric, but how our material will be used, the processing it goes through, challenges they face, and important characteristics for not only our customer but also their customer. This helps us fully understand the product requirements and allows us to create engineered solutions focused on creating the most value possible for the customer.

Once we understand their specific processing steps, their exact end-use, ideal performance gains or benefits, and what sets their products apart, we can help design modifications to Tex Tech fabrics to get them there.

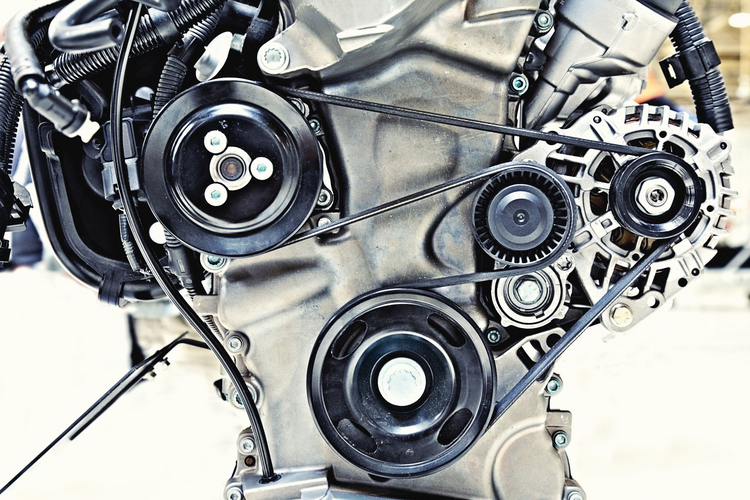

In our previous work with one customer in the power transmission belt industry, we discovered that by making just a few modifications to the baseline design of the fabric we could eliminate three processing steps in their production approach. While it may seem like a small change, the impact of eliminating those three steps was massive for the customer!

They had been having difficulty hiring the necessary personnel to work in their facility; one process in particular was especially hard for them to staff. As this was not a core strength of their company, it also led to a great deal of scrap loss. By modifying the product’s design, we were able to internalize the process. This solution expanded their capacity, removed a bottle neck, and together we reduced their scrap rate by over 20% and saved them hundreds of thousands of dollars!

That’s a great example of the impact of our strong relationships with customers. We’ve been working with many of our customers for more than 25 years, which has given us the great opportunity to form deep understandings of their businesses. Our team almost becomes an extension of their processing and manufacturing. The closer we get with our customers and the more entwined we become within their business — where our technical group is talking to their technical group and our product development teams are working jointly to tackle opportunities — together we find ways to unlock value across all different aspects of the businesses.