Chemical recycling of hard-to-recycle plastic waste

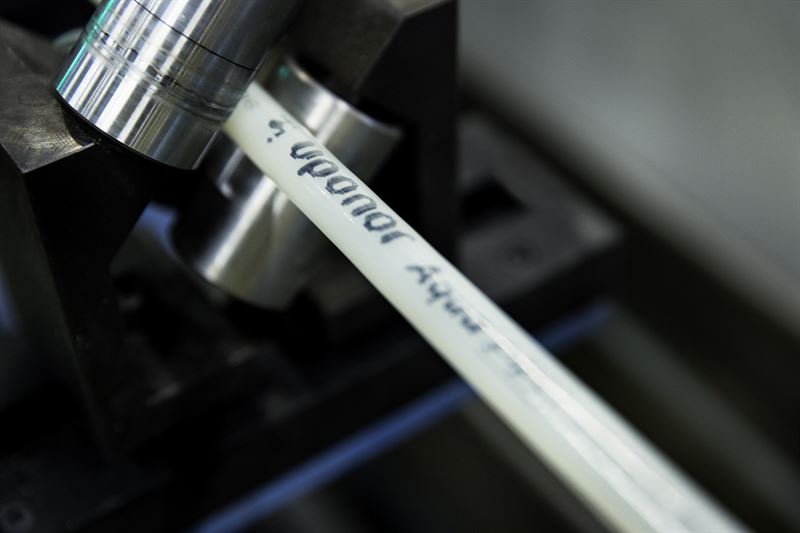

PEX pipes are an important contributor to energy-efficient heating and safe plumbing due to their strength, temperature resistance and durability, but the cross-linked polymer chains make them almost impossible to recycle using conventional recycling technologies.

The project demonstrates that chemical recycling can close the loop on hard-to-recycle plastic waste, transforming it into high-quality polymer feedstock and enabling the subsequent manufacture of products with the same quality and properties as in their previous life.

The collaboration will see Wastewise use its pyrolysis-based chemical recycling technology to liquefy industrial waste from Uponor’s PEX pipe production, breaking down the polymers back into their building blocks to create an oil-like recycled intermediate.This liquid is then co-processed at Neste’s oil refinery in Porvoo, Finland, and upgraded into recycled Neste RE, a drop-in feedstock for the production of new polymers. Borealis feeds this feedstock into its steam cracker, where it is polymerized into polyethylene as part of the company’s Bicycle C chemical recycling portfolio.

Finally, Uponor uses polyethylene to make new PEX pipe systems, which can then be reused in the building sector for heating, plumbing and cooling purposes – even for sensitive applications with high requirements, such as drinking water systems. The entire value chain is traceable through an ISCC PLUS-certified mass balance.

Previous Story

- Turning problem sea algae into a replacement for...

- PVC plastics now recyclable after breakthrough by Michigan...

- Canada’s single-use plastic ban takes effect on Dec....

- Tackling Plastic Pollution with a Net of Law...

- Plastic products firm acquired at 9.3x profits

- Could this new process finally turn polyethylene bags,...

- Researchers Develop Virus-Killing Degradable Plastic

- As Plastic Production Grows, Pledge Targets Resin Containment