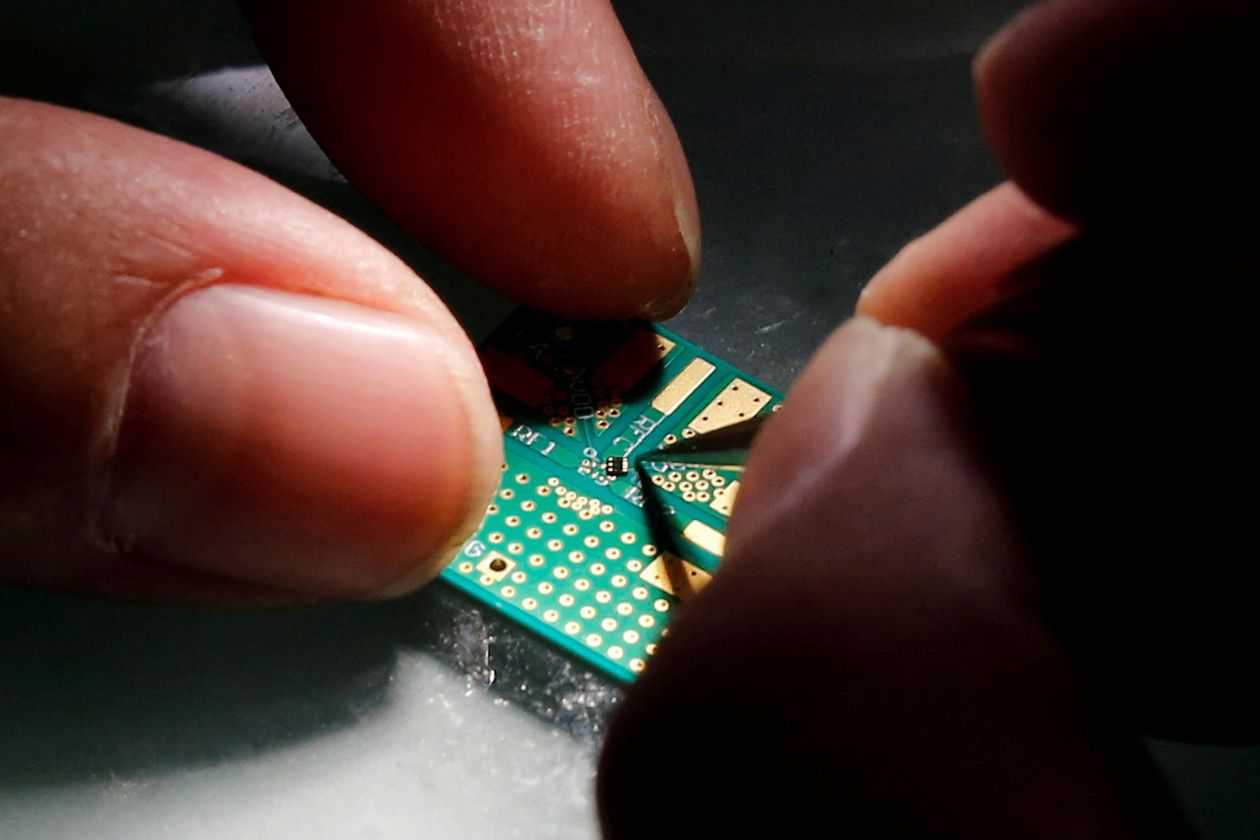

CIOs Stockpile Equipment, Examine Supply Chain Amid Chip Shortage

Image: Collected

Some chief information officers are bracing for the fallout from the worsening global semiconductor shortage by stockpiling more equipment and going for a closer look at the intricacies of their supply chain.

Chip shortages during the pandemic have hampered production of automobiles, computers, appliances and several other products, partly because of increased demand rather than enough supply. The problem is becoming more dire as a result of serious weather-related issues and natural disasters around the world.

“There’s kind of like a domino effect when there’s chip shortages, you just don’t know where it’s likely to hit next,” said Thomas Donnelly, chief information officer of New York-based software company BetterCloud Inc., which manages and secures software-as-a-service applications.

BetterCloud, which includes about 300 employees, is revisiting its supply-chain management and stockpiling more equipment for employees, which range from laptops and monitors to cameras for videoconferencing and keyboards. “It’s really unclear where these shortages can cause downstream impacts, so we have to adapt our safety stock across every little bit of technology we use,” Mr. Donnelly said.

Supply-chain constraints on chips and their pieces will continue steadily to affect chief Supply-chain constraints on chips and their parts will continue steadily to affect chief information officers working at a variety of companies, such as data center providers, server manufacturers, high-performance computing vendors and many electronics companies, said Gaurav Gupta, vice president analyst at technology research firm Gartner Inc.

“Anything you can imagine, any electronics today, has semiconductors,” he said. “If your company doesn’t have a solid volume or if you don’t have a major buffer stock, you then will be impacted one way or another, today or tomorrow.”

It's important that CIOs establish strategic relationships with suppliers of chips and chip-related pieces and enhance their semiconductor supply-chain knowledge to better understand where in fact the bottlenecks can occur, he said. Most CIOs have relationships with one direct chip supplier nonetheless they may not be familiar with the countless other layers of vendors within the supply chain, which range from the foundries to the packaging and testing centers, Mr. Gupta said.

Pure Storage Inc., a data-management and storage firm, spent time prior to the pandemic diversifying its supply chain in order that it isn’t reliant using one single vendor in a single specific geography, said Cathy Southwick, the company’s chief information officer.

As a result, the business isn’t facing significant issues linked to chip shortages. She's been communicating more often in the last year with the vice president of operations, Mike Fitzgerald, who oversees the company’s global supply chain. Ms. Southwick says it is crucial for CIOs to have deep insight in to the many vendors in the supply chain to protect against any disruptions. “If I await what to happen, it’s always harder to recover,” Ms. Southwick said.

Chip shortages during the pandemic have hampered production of automobiles, computers, appliances and several other products, partly because of increased demand rather than enough supply. The problem is becoming more dire as a result of serious weather-related issues and natural disasters around the world.

“There’s kind of like a domino effect when there’s chip shortages, you just don’t know where it’s likely to hit next,” said Thomas Donnelly, chief information officer of New York-based software company BetterCloud Inc., which manages and secures software-as-a-service applications.

BetterCloud, which includes about 300 employees, is revisiting its supply-chain management and stockpiling more equipment for employees, which range from laptops and monitors to cameras for videoconferencing and keyboards. “It’s really unclear where these shortages can cause downstream impacts, so we have to adapt our safety stock across every little bit of technology we use,” Mr. Donnelly said.

Supply-chain constraints on chips and their pieces will continue steadily to affect chief Supply-chain constraints on chips and their parts will continue steadily to affect chief information officers working at a variety of companies, such as data center providers, server manufacturers, high-performance computing vendors and many electronics companies, said Gaurav Gupta, vice president analyst at technology research firm Gartner Inc.

“Anything you can imagine, any electronics today, has semiconductors,” he said. “If your company doesn’t have a solid volume or if you don’t have a major buffer stock, you then will be impacted one way or another, today or tomorrow.”

It's important that CIOs establish strategic relationships with suppliers of chips and chip-related pieces and enhance their semiconductor supply-chain knowledge to better understand where in fact the bottlenecks can occur, he said. Most CIOs have relationships with one direct chip supplier nonetheless they may not be familiar with the countless other layers of vendors within the supply chain, which range from the foundries to the packaging and testing centers, Mr. Gupta said.

Pure Storage Inc., a data-management and storage firm, spent time prior to the pandemic diversifying its supply chain in order that it isn’t reliant using one single vendor in a single specific geography, said Cathy Southwick, the company’s chief information officer.

As a result, the business isn’t facing significant issues linked to chip shortages. She's been communicating more often in the last year with the vice president of operations, Mike Fitzgerald, who oversees the company’s global supply chain. Ms. Southwick says it is crucial for CIOs to have deep insight in to the many vendors in the supply chain to protect against any disruptions. “If I await what to happen, it’s always harder to recover,” Ms. Southwick said.

Source: https://www.wsj.com