Economical procedure makes Bhaskar Denim generally well known

Manageability is a critical issue in the denim field, the feasible center featured the Bhaskar Denim Industries Ltd's most recent advancements and improvements towards supportable denim. The organization is reliably attempting to decrease the ecological results with its supportable methodology.

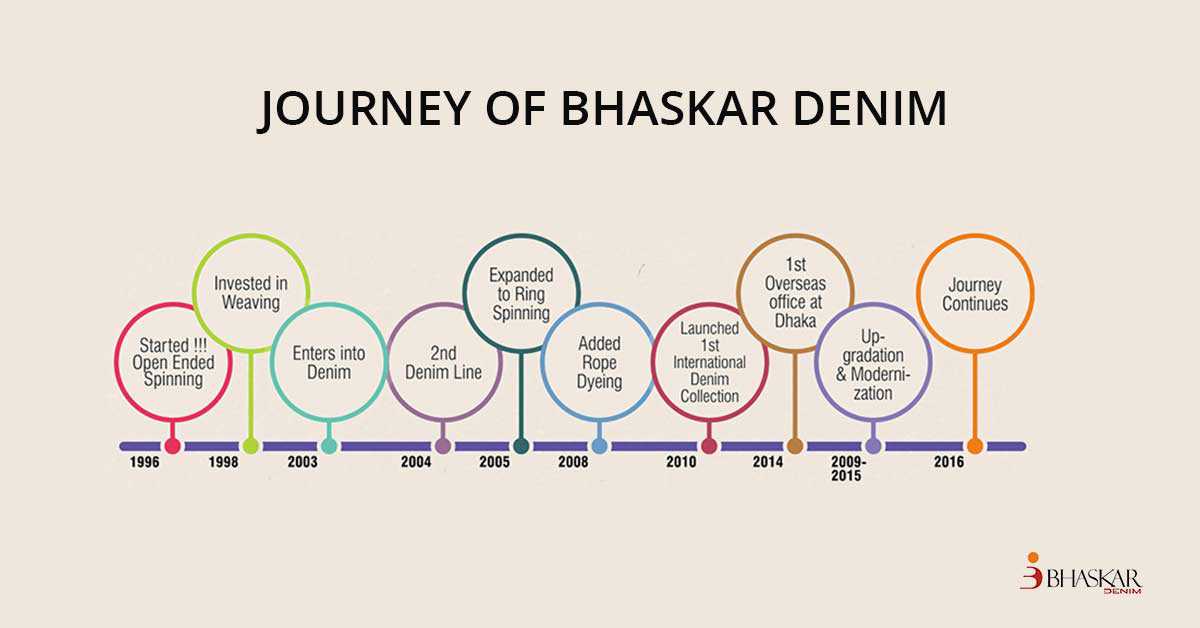

Bhaskar Industries Private Ltd, is a vertically incorporated denim plant under one rooftop, with a yearly limit of 44 million meters. As far back as its first loom kicked without hesitation in the year 1998 – it has stayed engaged and receptive to the requests of the Jeans-Scape. Consistency in quality, convenient conveyance and keeping pace with the changing design patterns, has given the organization an ideal situation in the denim business.

With a solid item improvement group at the center and skill of universal creators, Bhaskar is flooding ahead with a crate of imaginative items, to prime world markets in major garmenting focuses. Bhaskar has its own abroad and household workplaces and direct portrayals, in numerous nations.

Aside from India, Bhaskar fares to Sri Lanka, Korea, Egypt, Turkey, Germany, Vietnam, Columbia, Portugal, Chile and others. Bhaskar has a solid foundation in Bangladesh too to serve the material business in Bangladesh.

"Bhaskar thinks of International and Indian assortment for Spring Summer and Autumn Winter – with the assistance of worldwide denim fashioner, ably upheld by our in-house item advancement group," said Md. Nurul Momen, Country Head, Bhaskar (Bangladesh Operations).

Market patterns are examined visiting universal exchange fairs, creative thoughts are stamped taking preliminaries and the best of them are amalgamated for conclusive advancements.

"We co-make items with certain brands working intimately with their item improvement and advancement groups. For occasional introductions, support to exchange passages and factory weeks, we make pattern suitable piece of clothing adapting and washing utilizing our in-house clothing and other imaginative laundries. Our denim assortments are shown in material fairs the world over," he featured.

Bhaskar has confidence in the way of thinking of lessen reuse-reuse and is focused on making the earth increasingly supportable and better by:

1. Utilization of reused strands as a necessary piece of item advancement and development.

2. Zero water release.

3. Vitality protection.

4. Expanded utilization of water-sparing procedures in coloring and wrapping up.

5. Water collecting.

Bhaskar itself has turning back up delivering open end, ring and center spun yarn. Produces denim texture utilizing Airjet, Rapier, Dobby and jacquard lingers through slasher, rope and fluid indigo coloring technique.

They have been granted the confirmations of ISO-9001:2015,

ISO-14001:2015,

SA 8000,

BCI, OCS (ORGANIC), GOTS, GRS (GLOBAL RECYCLE STANDARD), OEKO – TEX, RCS.

Tags :

Previous Story

- Is denim offering new trusts in Bangladesh's clothing...

- DSCC sets aside an excessive amount of effort...

- BKMEA argues for facilitating bond arrangement

- Scent Control Textiles Market Analysis, Growth, Opportunities with...

- Promoting needs to concentrate on execution qualities

- Sending out cleaning clothes from cutting waste getting...

- ZDHC progresses material industry towards economical substance the...

- In the event that blockage finishes in streets,...