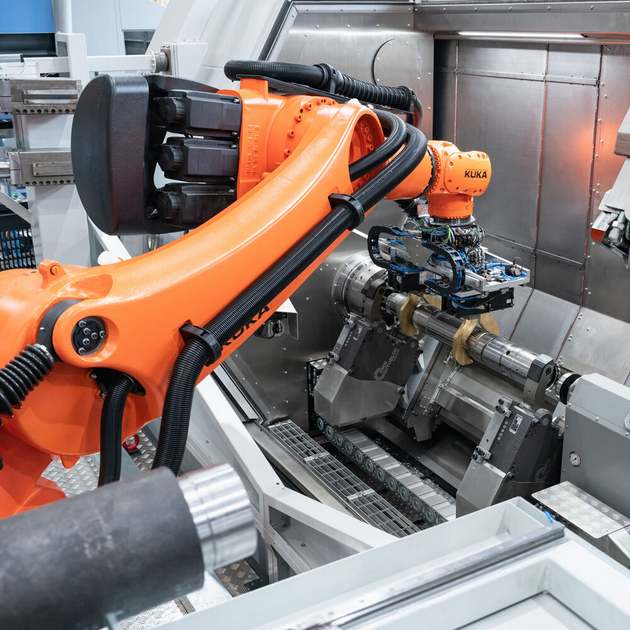

Mobile robot automates machining tasks

Image Collected

Automation tasks are becoming ever more challenging. Using intelligent software in combination with the relevant automation solutions not only enables workpieces to be loaded and unloaded but also means that machine tools can be set up fully automatically through automatic replacement of tools and clamping devices. Frai strives to be an innovative automation partner and is therefore developing highly flexible robot systems to respond to automation trends. Concepts such as the Mobilecell are a complete first and enable a wide range of expansion stages, making them as future-proof and competitive as possible.

Different industries, series production, small batch sizes, a wide variety of machine tools and the uncertainty of many manufacturers as to whether the current product will still be in vogue next year or become a slow seller - all this calls for flexibility in production. For automation, this means keeping pace with the increasing demands: it must produce autonomously around the clock, be flexible to use, and be Industry 4.0 compliant. In addition to the classic changeover of parts, automation also takes on the other tasks such as tool change, parts transport, logistics, host computer functions, part tracking and product history.

Different industries, series production, small batch sizes, a wide variety of machine tools and the uncertainty of many manufacturers as to whether the current product will still be in vogue next year or become a slow seller - all this calls for flexibility in production. For automation, this means keeping pace with the increasing demands: it must produce autonomously around the clock, be flexible to use, and be Industry 4.0 compliant. In addition to the classic changeover of parts, automation also takes on the other tasks such as tool change, parts transport, logistics, host computer functions, part tracking and product history.

Source: https://www.etmm-online.com