Shay Sethi talks about the continuing future of fabric recycling

Image: Collected

Clothing might not one thinks of when people think of plastic material pollution. But polyester, produced from crude oil, accocunts for half the full total fiber found in the global manufacture of textiles for apparel, upholstery, and other products, according to an examination by IHS Markit. Significantly less than 1% of garments obtain recycled into innovative clothing, and around 38 million metric a great deal of polyester from the style industry results in landfills each year, regarding to Shay Sethi, CEO of the start-up company Ambercycle.

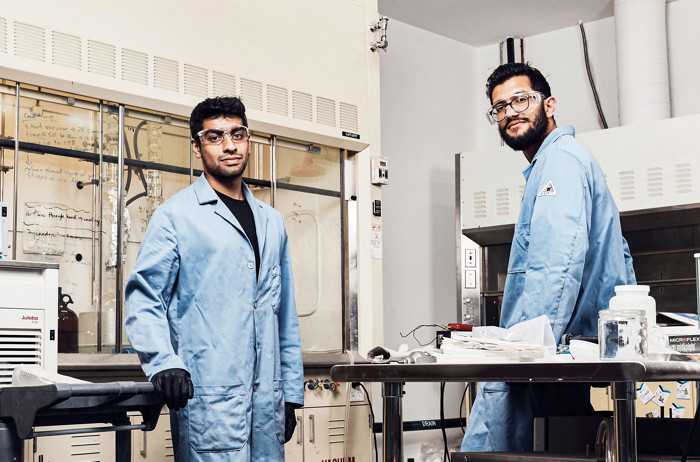

Adding benefit to textile trash may be the sole way to keep carefully the world from drowning in it, he says. He and his former college roommate, Moby Ahmed, developed ways to recover the pure and artificial polymers in textiles while these were pupils at the University of California, Davis. They cofounded Ambercycle in 2015 to scale up the procedure and show that maybe it's done cost properly. In 2016, they earned the H&M Foundation’s annual Global Transformation Award, which helped fund technology advancement. The business launched a product line of recycled garments with Los Angeles-based street-wear brand Come Back as a Flower in December.

Sethi says the toughest activity is to make the price tag on recycled polyester competitive with that of virgin polymer, at $1 per kilogram. That is achievable by addressing commercial scale, nonetheless it takes period to get there, he says. Prachi Patel talked with Sethi about the challenges of shaking up a big, established industry. The next interview was edited for duration and clarity.

The waste operations industry hasn't seen many technological change. Plastic normal water bottles are incredibly clean materials, so you can recycle them employing rudimentary technology-basically simply melting and re-forming. It’s very archaic.

Most of our textile today-T-shirts, household furniture, carpets-is some form of polyester blended with cotton or perhaps acrylic or perhaps spandex. This helps it be very difficult to recycle. Ambercycle is normally developing a sophisticated recycling method for these textiles. Classic garments enter into the process and so are converted to their initial constituents, and the ones molecules can be utilised to make the same garments. We recycle the polyester and have partners who cope with the cellulose and spandex parts.

The theory is to build really elegant recycling processes using advanced chemistry and engineering and build a much better back end for losing things and making new stuff. We’re starting with polyester in textiles but will expand to create additional polyester streams circular aswell. We are portion of a new wave of increased circular materials companies that can better recycle these complex materials.

What's the recycling process?

It’s essentially a molecular separation of different components in a garment. A complete T-shirt switches into a reactor, and through a patented process, we're able to recover the polyester and re-form it right into a yarn.

Our process is a combination of existing chemical substance recycling with smart engineering that makes the procedure continuous. It’s simple, quickly, and not strength intensive. Producing virgin polyester from oil takes a lot of energy. Our method consumes 80 to 90% less strength per kilogram of materials produced. Every industrial method dreams of a 98-plus percent yield, and we’re getting there.

At this time, we are running a pilot plant that processes tens of kilograms of clothing a time to verify the technical method. And we are creating a demonstration plant which will create a metric ton of materials each day; that’s 10,000 to 15,000 garments. We’ll prove our idea with the demonstration plant and find companions for a industrial plant.

Source: https://cen.acs.org

Previous Story

- The brand best known for its hydration packs...

- Clothing companies possess a rare possibility to be...

- Kenilworth College students Nonprofit Clothing Line Come to...

- What sort of Howard University senior switched a...

- In the textile industry, old is becoming increasingly...

- Vietnam stole a good march on Bangladesh in...

- Made in Bangladesh’ may in the near future...

- Here's Another Opportunity Department Stores Can't Capitalize On