Apparel task uncertainty on the wane

Image: Collected

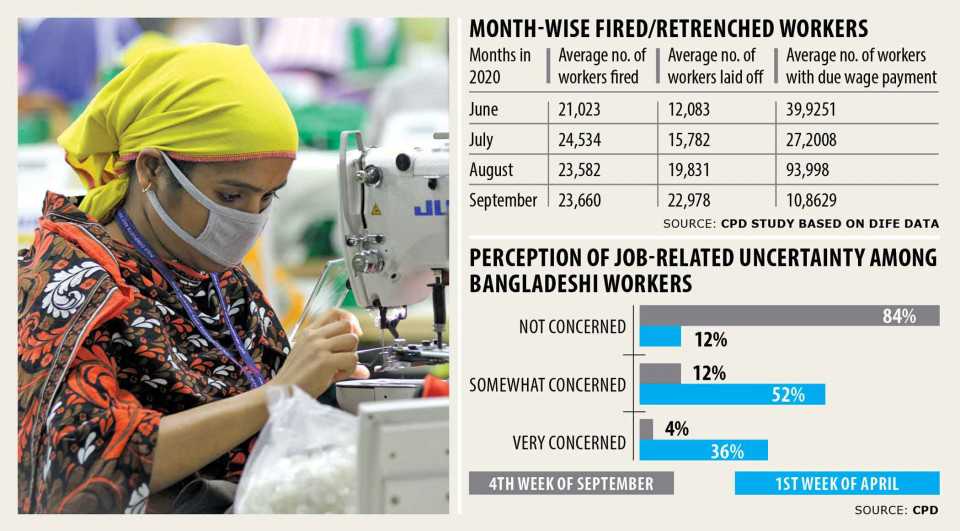

With recuperation of international suppliers and brands' do the job orders, job uncertainty among Bangladesh's garment staff has been alleviated to 4 per cent in September this past year from 36 % in April, says a CPD study.

Factory workloads have risen previous that on Sri Lanka, another main South Asian garment exporter. Factory managements have been recruiting workers on a daily basis, said the analysis made public yesterday.

Bangladesh's garment export provides been building a slow recovery for detrimental effects arising anew for the pandemic's second wave.

Bangladesh cannot invest a whole lot in online sales, which includes now emerged as the major engine for retail organization, said Khondaker Golam Moazzem, research director of the Centre for Insurance policy Dialogue (CPD).

Different government supports must be continuing for mid and long-term recovery of the sector's business, he said while presenting the study's findings at a digital discussion.

Some 60 % of factories have started recruiting staff afresh, he added.

The CPD and Southern Voice, a network of over fifty think tanks from Africa, Asia and Latin America, jointly organised the debate on "Recovery of the Clothing Sector from the Covid-19 Crisis: Is a Value Chain Based Alternative Possible?".

CPD Chairman Rehman Sobhan suggested a regional response for the garment trade's restoration, reasoning that the neighbouring countries have already been facing the same difficulties.

He also recommended introducing a micro-social insurance scheme for employees influenced by the Covid-19 fallout. Factory owners, the federal government and even workers and buyers could donate to the formation of this insurance scheme fund, he explained.

Moderating the conversation, Mustafizur Rahman, a distinguished fellow by the CPD, proposed to get a global compact meant for garment businesses to produce a faster recovery and pertaining to supporting factory owners and employees.

Ziaur Rahman, Swedish retail giant H&M's regional manager for Bangladesh, Pakistan and Ethiopia, advocated for increasing workers' minimum amount wage as their monthly pay was even now low.

He also said that H&M had started paying higher prices for Bangladesh's garment things found in tune with the last upsurge in wages.

"We will boost the selling price of garment products if the wage of personnel is elevated again," he said.

Rahman said China, Vietnam and Cambodia were building a faster recovery running a business because Bangladesh's goods can be characterised as being fundamental and by their large volumes.

Bangladesh must improve its product diversity and innovation for faster recovery and sustainability on this organization, he added.

There is no disruption or cancellation of work orders being placed by H&M possibly amidst the pandemic, he said.

He suggested shifting to man-made fibres to lessen overdependence about cotton and grab a good bigger global industry share.

KM Abdus Salam, secretary to the Ministry of Labour and Job, said Tk 50 crore was obtainable with the ministry for disbursement through social safety net programmes among staff retrenched through the pandemic.

Some 10,000 personnel have been listed as far as beneficiaries and each would get Tk 3,000, he said. The European Union and German government furnished the fund as a donation.

The secretary also said the federal government would also make donations to the fund later on and the ministry would stay open to donations from any other agency, body or country for personnel to continue to get supports.

Rubana Huq, president of the Bangladesh Garment Manufacturers and Exporters Association (BGMEA), found parts of the study's findings to be somewhat conflicting.

For instance, it explained that garment export revenue were declining but also factory managements environment higher production targets.

In addition, the managements were reported to be simultaneously hiring and firing workers, she said, urging to activate in conversion with info.

Huq also said between April and September, prices of Bangladeshi garment things dropped 4.82 % although development costs continued to increase while demand declined 11 % in the US and 16 per cent in the EU.

However, the government has been putting pressure along garment manufacturers to get started on repaying the loans received through the state's stimulus package meant to offset the fallouts of Covid-19, she explained.

Harry Verweij, ambassador of HOLLAND to Bangladesh, said his government played a good pioneering role among the EU nations refraining from cancelling do the job orders.

He said The Netherlands and Denmark from the EU have particularly come forward to talk about the risk of shopping for garments through the pandemic.

Amirul Haque Amin, president of the National Garment Staff Federation, suggested the government amend the existing law centring laying away workers.

Various factories went for layoffs for four to five months at a time although the labour regulation provisions allow just two months, Amin said.

Over two lakh employees lost their jobs through the pandemic, he said, adding that the scope for overtime has been reduced substantially as a result of fewer work orders.

So just domestic solutions aren't enough to solve the issues and lots of global initiatives are necessary for long-term solutions, he added.

Kalpona Akter, executive director of the Bangladesh Centre for Worker Solidarity, said employees were provided 60 % of their salaries for the present time whereas it was difficult to survive despite having the full amount.

She also urged the federal government to make sure continuation of the proposed 5 % annual salary increment.

Bangladeshi factory owners could not avail regional cooperation found in sourcing raw materials through the pandemic, said Arshad Jamal Dipu, vice-president of the BGMEA.

So a more robust sub-regional cooperation is essential, he said.

Commerce Minister Tipu Munshi hinted that more time would be allowed for repaying the stimulus bundle loans.

He also sought greater cooperation among the government, stores, factory owners, union leaders, workers and governments of countries sourcing the merchandise for overcoming the sector's challenges.

Source: https://www.thedailystar.net

Previous Story

- ‘Completion of Padma Bridge to boost Bangladeshi economy’

- Bumpy road awaits exporters

- Achievements from stimulus packages are good: Mannan

- Formally approached embassy for rail, road links between...

- 'LDC graduation a chance for Bangladesh'

- GDP growth data not credible, says CPD

- Defer graduation from LDC golf club to tap...

- ‘Rural economy to be under great pressure with...