Bally Ribbon Mills Announces New Group of Advanced Textile Products

Image: Collected

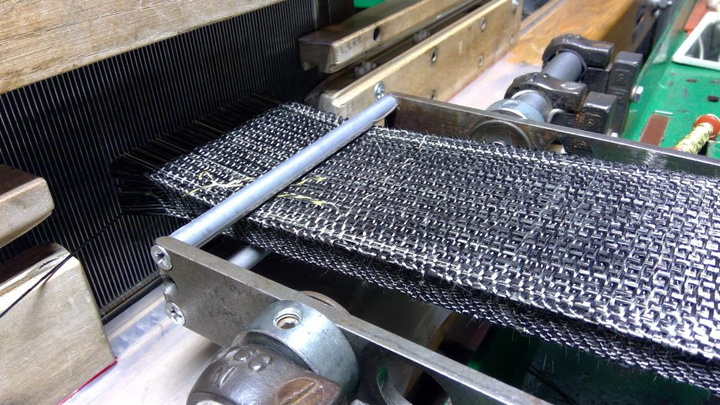

Bally Ribbon Mills announces its hottest type of advanced textile products to improve part functionality and utility. As companies demand higher sturdiness and product differentiation, BRM has innovated using its E-WEBBINGS and TPCM thermoplastic materials. Both products offer superior features, including lighter weight, specific strength, durability, stability, abrasion resistance, and sustainability.

BRM’s advanced textile products are well suited for electronic transmission data, energy storage, and manufacturing automation. Dealing with companies that include NASA, Tier 1 Defense suppliers, together with directly with the Department of Defense (Army, Air Force), BRM is rolling out advanced textiles found in parachutes, safety harnesses, personal protective equipment, and chemically resistant webbing. BRM is relative to safety standards, specifications and certifications, including ISO9001, AS9100, ISO13485, ISO14000, NFPA, ASTM, ANSI, *UL, and CSA.

E-WEBBINGS are narrow-fabrics that are conductive, enabling the electronic transmission of data sensations (light, noise, vibrations, heat), and power that can be kept or used to actuate/transform objects. Unique conductive fibers could be woven together with other fibers and can be used in embedded sensors in both wearable and integral technology, like the Internet of Things.

TPCM thermoplastic composite materials are 2-D or 3D-woven, thermoplastic structures for incorporation into composite parts produced within varied, continually-evolving molding processes. The woven structural shapes are being used in hybrid composite structures used in numerous industries, including aerospace/aviation, automotive/transportation, defense, architecture/infrastructure, marine and sports/recreation.

BRM customizes weave designs to change performance properties, offering expert functions for custom options and configurations to optimize designs. BRM’s laboratories consider application details, width, tensile strength, elongation, color, quantity, and other special requirement with custom-made advanced textile products.

BRM’s advanced textile products are well suited for electronic transmission data, energy storage, and manufacturing automation. Dealing with companies that include NASA, Tier 1 Defense suppliers, together with directly with the Department of Defense (Army, Air Force), BRM is rolling out advanced textiles found in parachutes, safety harnesses, personal protective equipment, and chemically resistant webbing. BRM is relative to safety standards, specifications and certifications, including ISO9001, AS9100, ISO13485, ISO14000, NFPA, ASTM, ANSI, *UL, and CSA.

E-WEBBINGS are narrow-fabrics that are conductive, enabling the electronic transmission of data sensations (light, noise, vibrations, heat), and power that can be kept or used to actuate/transform objects. Unique conductive fibers could be woven together with other fibers and can be used in embedded sensors in both wearable and integral technology, like the Internet of Things.

TPCM thermoplastic composite materials are 2-D or 3D-woven, thermoplastic structures for incorporation into composite parts produced within varied, continually-evolving molding processes. The woven structural shapes are being used in hybrid composite structures used in numerous industries, including aerospace/aviation, automotive/transportation, defense, architecture/infrastructure, marine and sports/recreation.

BRM customizes weave designs to change performance properties, offering expert functions for custom options and configurations to optimize designs. BRM’s laboratories consider application details, width, tensile strength, elongation, color, quantity, and other special requirement with custom-made advanced textile products.

Source: https://www.utilityproducts.com

Tags :

Previous Story

- Export of textiles jumps 30pc in March

- Richmond native becomes curator of clothing and textiles...

- Carrefour expands blockchain traceability to textile products

- Bangladesh to seek remedy for Indonesia safeguard duty

- H&M & Inter IKEA Group Back Tree To...

- Engineering Value: Choosing the right Fabric for Proper...

- Textile Industry: How to Analyze Additives Utilizing a...

- In the textile industry, old is becoming increasingly...