Plastic wastes no more a bane but a boon

Image collected

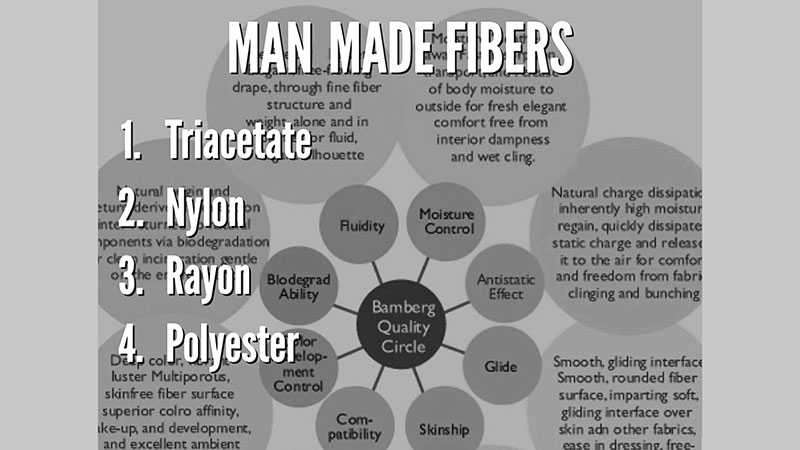

Plastic wastes of late are considered an evergrowing hazard that pollutes the environment in land and sea. But a new hope has been raised with the nascent make use of plastic wastes. It has been learned that new fibre from plastic wastes fires up hopes whereby the bane of plastic wastes becomes boon lately in the sort of new synthetic fibre (MMF). It's been found that MMF comes as a spur to financial prospects. It promises not only to open up an opportunity to turn plastic wastes - a substance dangerous to environment - into assets but also brighten the future of Bangladesh apparel business. Predicated on running their startups already, a few trailblazers in this business of turning trash into treasures exuded such hopes. The world apparel consumers have become very much conscious about green world and chosen less-nature-damaging items. In consequence, the demand for MMF made apparel has been increasing.

The share of MMF based apparel, according to Bangladesh Garment Manufacturers and Exporters Association (BGMEA), is just about 45 percent of global trade. Which is growing at a 5.0 percent compound gross annual growth rate (CAGR). The global trade in MMF based products now stands at 200 billion US dollar. The share of Bangladesh is merely a peanut 5.0 percent while its competitor Vietnam shares a lot more than 10 percent. For the sustainability of the apparel industry, Bangladesh will have to grab more market share in the global garment business. Sources in the business circles maintain that although the pace continues to be slow, the neighborhood garment manufacturers are also choosing MMF.

Compared to its two competitors - China and Vietnam - the united states still goes banking on cotton-based products. Because of this the apparel product basket of Bangladesh is narrow. Experts say that although the potential still remained untapped, Bangladesh has immense scope of developing multi faceted products from man made fibres. They say the establishing of MMF based spinning mills is little expensive. But investors should accept it, taking into consideration the greener world and the demand of the world market. A few of such manufacturers are top-notch upbeat about the chance. They, however, said that cotton-made fibre prices do fluctuate predicated on petroleum price.

As we do not produce cotton but we are heavily reliant on it. But we are able to expand our market horizons by beginning to produce MMF.

Regarding its technology, it isn't at all a concern because technology is a commercial product. So, if Bangladesh may bring out the right product, technology, and recycleables, is not a concern. The Bangladesh Textile Mills Association (BTMA) said that, on average, Bangladesh imported 78,000 tonnes of polyester staple fibre, 29,000 tonnes of viscose staple fibre and 5 thousand tonnes of Tencel fibre. If local spinning mills started production of MMF through the use of locally available plastic products, especially plastic containers, the import of such substances could be reduced to half. There are trustworthy data about the locally available plastic wastes. It's been sensed that thousands of tonnes of plastic wastes could possibly be obtained from the neighborhood source. One firms all ready shows the way to new ventures with the innovation

The global demand for MMF based apparel products is increasing. In tune with it the Debonair Group has undertaken a project to turn discarded plastics into yarns and fibers. The venture is for manufacturing jacket, padding and quilts. In what's otherwise viewed as hazard, the investor circles also find a business bonanza in it. Foreign investors too have grown to be keen to purchase the plastic recycling sector because of rise in the demand for MMF based apparel products. The administration, they think, should give especial focus on bringing Foreign Direct Investment (FDI) in the plastic recycling sector. That could go a long way in developing plastic recycling industry in the united states to meet the demand for MMF based apparel products for local and foreign markets.

This can help us reducing or eliminating the demand for cotton made fibres that people presently import to meet up the demand for the country’s apparel sector. This will save a large amount of forex expenditure for the united states.

In fiscal 2018-2019, Bangladesh imported 6.9 million bales of cotton from the world to meet up its demand. The country annually spends 3.5 billion US dollar in importing cotton. Because the RMG sector of the country is a major forex earning source and the united states isn't a cotton making one we must depend on cotton import. The MMF based apparel products may turn a boon for the country’s export sector and help us turn out from much necessary dependence on cotton imports in the near future.

Source: http://www.theindependentbd.com

Tags :

Previous Story

- China’s Fruit Import and Export Statistics for 2019...

- Bangladesh cashes in on China’s lost business

- Bangladesh-China trade, infra coop may be affected temporarily:...

- Chinese envoy sees no trade disruption with Bangladesh

- Roaring Bangladesh economy a boost to Asian dry...

- Coronavirus outbreak: Khulna’s crab, eel trade losing Tk...

- Coronavirus hurts local businesses

- China coronavirus epidemic poses a threat to BD...